This room looks empty doesn't it?

Well, apart from the air, and the invisible stuff on the surfaces, it is. But how clean are the air and the surfaces? The answer is probably, pretty dirty. Most indoor spaces are teeming with bacteria, and maybe viruses, and probably volatile organic compounds.

Some or all of these can make you and your staff unwell, perhaps dangerously so, and create unpleasant odours, or poor air quality, leading to lower productivity and absenteeism.

Isn't it time to do something about that, for everybody's health?

Especially if it improves your bottom line at the same time?

So, why do we make such a fuss about the size of the nanoparticle we use?

Well, first of all, we know we have a unique advantage. Ours is the smallest available. But why is is that important?

It's all about surface area. The smaller the particles, the greater the surface area of the ultra thin film. This applies equally to surface treatment or light source.

Take a cube. Any size cube. A one metre cube. It has 6 equal sides.

Now lay it flat. Measure the surface area.

Next, divide the one metre cube into 8 equal smaller cubes. Now lay them flat. What do you notice? The surface area has doubled.

And the same is true of one metre cubes, or one nanometre cubes. (Our nanoparticles aren't cubes by the way, but you get the idea.)

So, the reason size matters is...if our nanoparticles are smaller, more of them fit in the same film, and their surface area is much larger. So as an engine of oxidation, they are much much more efficient. If you keep making smaller cubes....

...the surface area becomes immense. More surface area means more area for reactions. More reactions mean more oxidants.

And, a side effect of the extra efficiency, is they don't need a chemical binder to work efficiently. Look closely at other products claiming to use similar nanotechnology. They are not as efficient, so they contain chemical binders. And chemical binders are not good.

So now you know why nanosize matters, maybe you want to know who discovered this, and how and when?

Well. Titanium Dioxide or TiO2 is the naturally occurring oxide of titanium, it has for centuries seen a wide range of applications for every day use, from paint to sunscreen to food colouring to cosmetics, the list goes on.

The answer is that this particular scientific process, called Photocatalytic Oxidation, was discovered by Professor Akira Fujishima in Japan in 1967.

After his serendipitous discovery, research throughout the world took off, with the aim of trying to create products that could benefit from this science, and the research took two directions-

- Using TiO2 as an additive to products e.g. glass/window panels, bench tops and paints

- Using TiO2 as a coating on products after manufacture

The latter was the most successful, due to TiO2's need to absorb direct light and not be obstructed by other matter, to experience full capabilities...

So this process has been around for 47 YEARS. It's well documented, and you will find loads of good hard peer-reviewed research out there. We list some of it on this website. We encourage you to read it, check our claims, look at other companies and then return. You will find that the size of our nanoparticles is as important as we say it is. Our product works better.

At this point its useful to understand Photocatalysis

- Let’s have a look at a similar process, photosynthesis. In photosynthesis, plants and other autotrophic (self feeding) organisms, absorb light to create energy to fuel their activities, carbohydrates such as sugars are synthesized from carbon dioxide and water, and oxygen is also released, mostly as a waste product

- In photocatalysis, a catalyst (TiO2), accelerates a photo reaction from either sunlight, or artificial light (if TiO2 particles are small enough), this acceleration creates, electron-hole pairs, which generate free radicals (unpaired atom, molecule or ions), these free radicals are highly reactive toward other substances, and therefore oxidize them, leaving only traces of carbon dioxide and water.

- The free radicals high reactivity to other substances sets in motion an oxidation process that is, fast and ongoing, as long as their is a light source

- Benefits seen are the reduction or elimination of, micro organisms, volatile organic compounds and other substances harmful to inhabitants or detrimental to surfaces

So what can be treated? Here are a few substances up for oxidation (examples only, the spectrum is so broad)

- Micro Organisms - viruses, bacteria, mould, fungi etc....

- Volatile Organic Compounds-, formaldehyde (found in paints and other coatings and emitted into air throughout their lifespan), benzene ( found in tobacco smoke, stored fuels, exhaust from cars) and many more....

- Odours - eliminates or reduces all

So via oxidation, we see an elimination, or ongoing reduction of many of the substances, that are or can be harmful or a nuisance in our everyday lives.

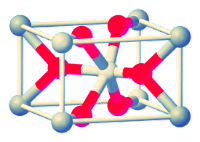

OK, great. Let's see it in action. Here's a diagram showing the process. Remember, the reaction os the same whether the TiO2 is a surface film or a film bonded to a light source, by which we simply mean a light bulb or a fluorescent tube.

The light source generates UV, which hits the TiO2 film, and the oxidant is the result of the reaction. It surrounds and acts upon the organic matter, disintegrates it, and releases water and carbon dioxide.

But there's more.

So small are the TIO2 nanoparticles applied to the surface, that they cause it to become superhydrophilic, which simply means they love water.

Superhydrophilic surfaces reduce the contact angle of water on their surface so the water sheets off

Super-hydrophilic contact angles make for ease of dirt and oil release by water sheeting contaminants off. And keep in mind that these contaminants have already been oxidized making for even easier removal

So the Benefits include, less spotting, ease of dirt and oil release, reduction in cleaning costs and faster evaporation

There are even some useful side effects, at no extra charge...

TIO2 naonparticles coated on a surface provide good UV protection. Check a tube of sunscreen. TiO2 is used in sunscreens to absorb damaging UV rays.

TiO2 protects paint, plastics and textiles from damaging UV rays. This is done by absorbing the UV rays and changing them into small amounts of heat which dissipate quickly without damage to the structure of coated surface.

TiO2 coated surfaces can approach 100% absorption (90% absorbed 10% scattered), so for example that would be a rating of SPF 50+ on textiles.

Other benefits include, but are not limited to, extended substrate lifespan, reduced fading, reduced maintenance costs (e.g. longer intervals between painting).

And...TiO2 nanoparticles coated on a surface provide corrosion protection.

- TiO2 provides a corrosion resistant oxide barrier when applied to metals

- TiO2 physio-chemically binds to substrate and acts as a passivation layer on metals reducing rust formation

- TiO2 can also inhibit further corrosion on already affected substrates

So to summarise, the science is serious, well established, well known, well documented. The nanoparticles we use are the smallest available, which means more efficient, and without the need for nasty chemical binders.

A complete green solution, with endless applications, and all because nanosize matters.